Car horn accessories plastic material

| Unit Price: | 10000 USD |

|---|---|

| Min. Order: | 1000 Set/Sets |

| Packaging: | Wooden box |

|---|---|

| Productivity: | 500000shots/mold life |

| Brand: | Ceeto |

| Transportation: | Ocean,Air,Land,Express |

| Place of Origin: | China |

| Supply Ability: | 30pcs/month |

| Certificate: | ISO |

| HS Code: | 8480790090 |

| Port: | Ningbo,Shanghai |

Basic Info

Model No.: CT-10552

Click on the follow link to find out more information: https://www.ceetomold.com/automotive-exterior-plastic-injection-mould/

Company Info

- Company Name: Zhejiang Ceeto Mold Co.,Ltd.

- Representative: WANG JUAN

- Product/Service: Plastic Injection Molds for Automotive , Plastic Injection Molds for Washing machines , Plastic Molds for air condition , Medical Consumer Goods Plastic Injection Mould , Die Casting Moulds and Products , Plastic Molds for Daily commodities

- Capital (Million US $): 10,000,000RMB

- Year Established: 2018

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 71% - 80%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 2

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No.78 Baiyunshan Road, Ningbo,China

- Contact Person: Ms. Jenny Wang

- Tel: 86-574-86863623

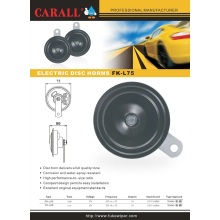

Premium Related Products

Other Products

Hot Products

Autoparts Vehicle Ramp for Wheelchair for Van, MPV, SUV, Motorhohe, ISO/Ts 16949Auto Accessory, Vehicle Folding Ramp for WheelchairElectric City Bus Bridge, Bus RampsCar Horn-K80A (3A, 12V)Car Accessories Rear Wiper Blade for BMW and Opel (S108)Auto Accessories Flat Wiper Blade (S910) for Japanese CarWiper Blade for Special CarsAuto Parts Frameless Car Windshield Wiper for Audi (S650)Auto Parts for Vehicle Snow WiperRear Wiper Blade with OE Adaptor Used for Golf, Polo and TiguanAuto Parts Hybrid Wiper BladesUniversal Wiper BladeAuto Parts Frame Wiper Blade (T650)Car Wash Cleaner, Car Wash ShampooCar Accessories Multi-Fit Flat Wiper Blade with 10 AdaptorsAuto Accessory, Vehicle Ramp for Wheelchair